Butterfly Valves: The Ultimate Guide Values

Butterfly valves are versatile, cost-effective flow-control devices widely used in industries like chemical processing, water treatment, oil and gas, and HVAC. Their simple design, quick operation, and compact size make them ideal for large-diameter pipelines and systems requiring efficient shutoff or throttling. Below is a comprehensive guide to butterfly valves, covering their types, design, applications, advantages, and key selection criteria.

1. What is a Butterfly Valve?

-

Design: A circular disc (the “butterfly”) rotates 90° around a central shaft to control flow.

-

Open position: Disc aligns parallel to flow, allowing maximum throughput.

-

Closed position: Disc rotates perpendicular to block flow.

-

-

Key Components:

-

Body (cast iron, stainless steel, PVC, etc.).

-

Disc (often metal or resilient-coated).

-

Seat (elastomeric or metal for sealing).

-

Shaft (connects disc to actuator).

-

Actuator (manual lever, gearbox, electric, pneumatic, or hydraulic).

-

2. Types of Butterfly Valves

A. By Seat Material

-

Resilient-Seated Butterfly Valves:

-

Seat: Soft elastomers (EPDM, Nitrile, Viton®) for tight shutoff in low-pressure/temperature applications.

-

Use: Water, air, mild chemicals.

-

-

High-Performance (HP) Butterfly Valves:

-

Seat: Metal (stainless steel, Inconel) or PTFE-lined for high-pressure/temperature or abrasive fluids.

-

Use: Oil and gas, steam, corrosive chemicals.

-

-

Triple-Offset Butterfly Valves:

-

Design: Metal seat with conical geometry for zero leakage in critical applications (e.g., cryogenics, refineries).

-

Use: High-pressure/temperature, fire-safe systems.

-

B. By Connection Type

-

Wafer-Style: Clamped between flanges (lightweight, cost-effective).

-

Lug-Style: Threaded inserts for bolt connections (allows valve removal without disassembling pipelines).

-

Flanged: Integral flanges for direct bolting.

-

Double Flanged: For high-pressure systems.

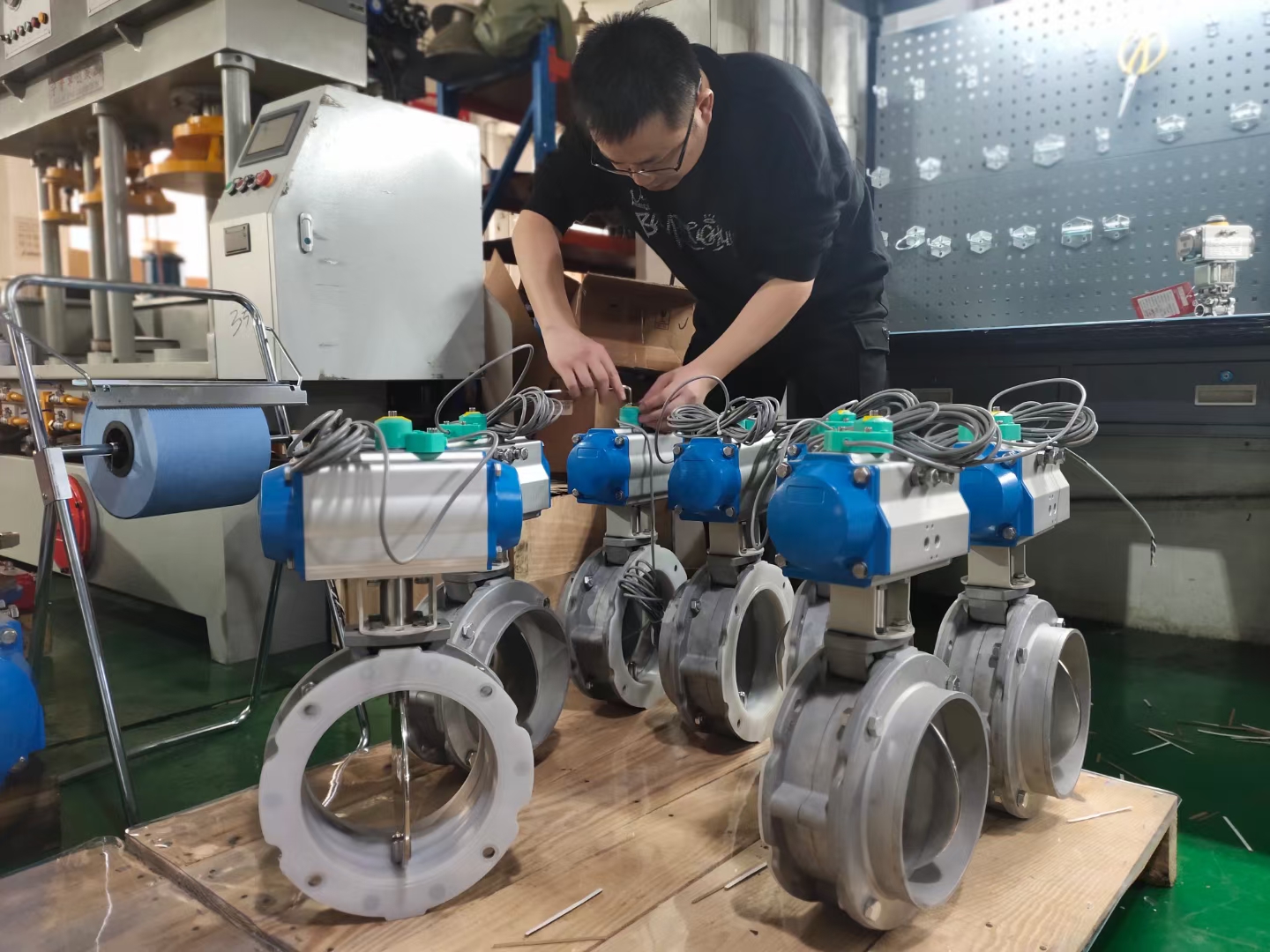

C. By Actuation

-

Manual: Hand lever or gear-operated.

-

Electric: Motorized actuators for automation.

-

Pneumatic/Hydraulic: For rapid response in hazardous areas.

3. Key Applications in the Chemical Industry

-

Flow Regulation: Adjusting chemical dosing rates.

-

Isolation: Shutting off pipelines during maintenance.

-

Slurry Handling: Resilient-seated valves for abrasive mixtures.

-

Corrosive Fluids: Valves with PTFE or Hastelloy components.

-

High-Purity Processes: Sanitary butterfly valves for pharmaceuticals.

4. Advantages of Butterfly Valves

-

Compact & Lightweight: Easier to install than gate/ball valves.

-

Quick Operation: 90° rotation enables fast shutoff.

-

Cost-Effective: Lower material and maintenance costs.

-

Low Pressure Drop: Minimal flow restriction when fully open.

-

Versatility: Suitable for liquids, gases, and slurries.

Conclusion

Butterfly valves are indispensable in the chemical industry for balancing performance, cost, and reliability. Selecting the right type—resilient-seated, high-performance, or triple-offset—depends on fluid characteristics, pressure/temperature conditions, and compliance needs. Always prioritize material compatibility and certifications (e.g., API, ATEX) to ensure safety and longevity.

" alt="publication image" class="mil-scale-img">

" alt="publication image" class="mil-scale-img">