Play

Open

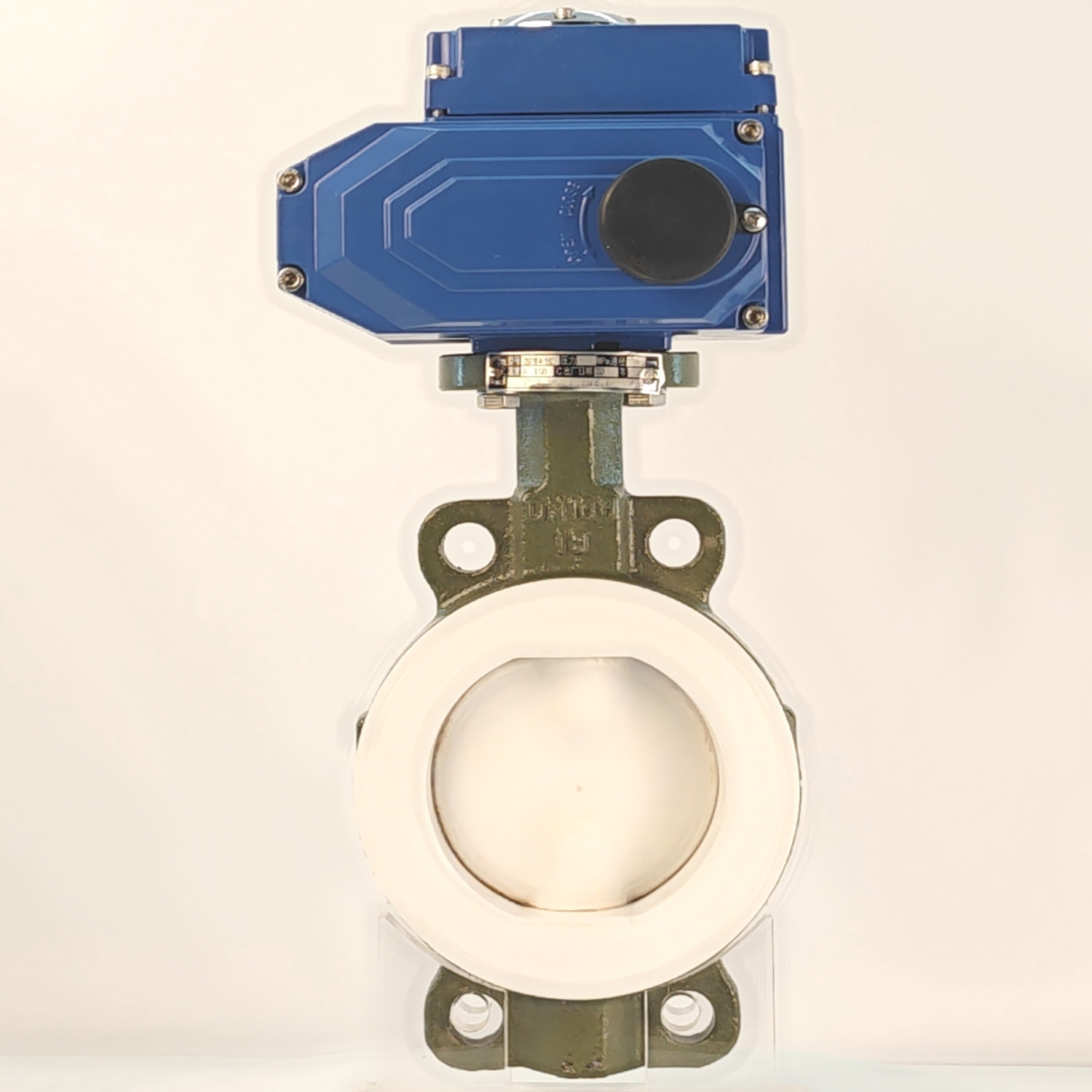

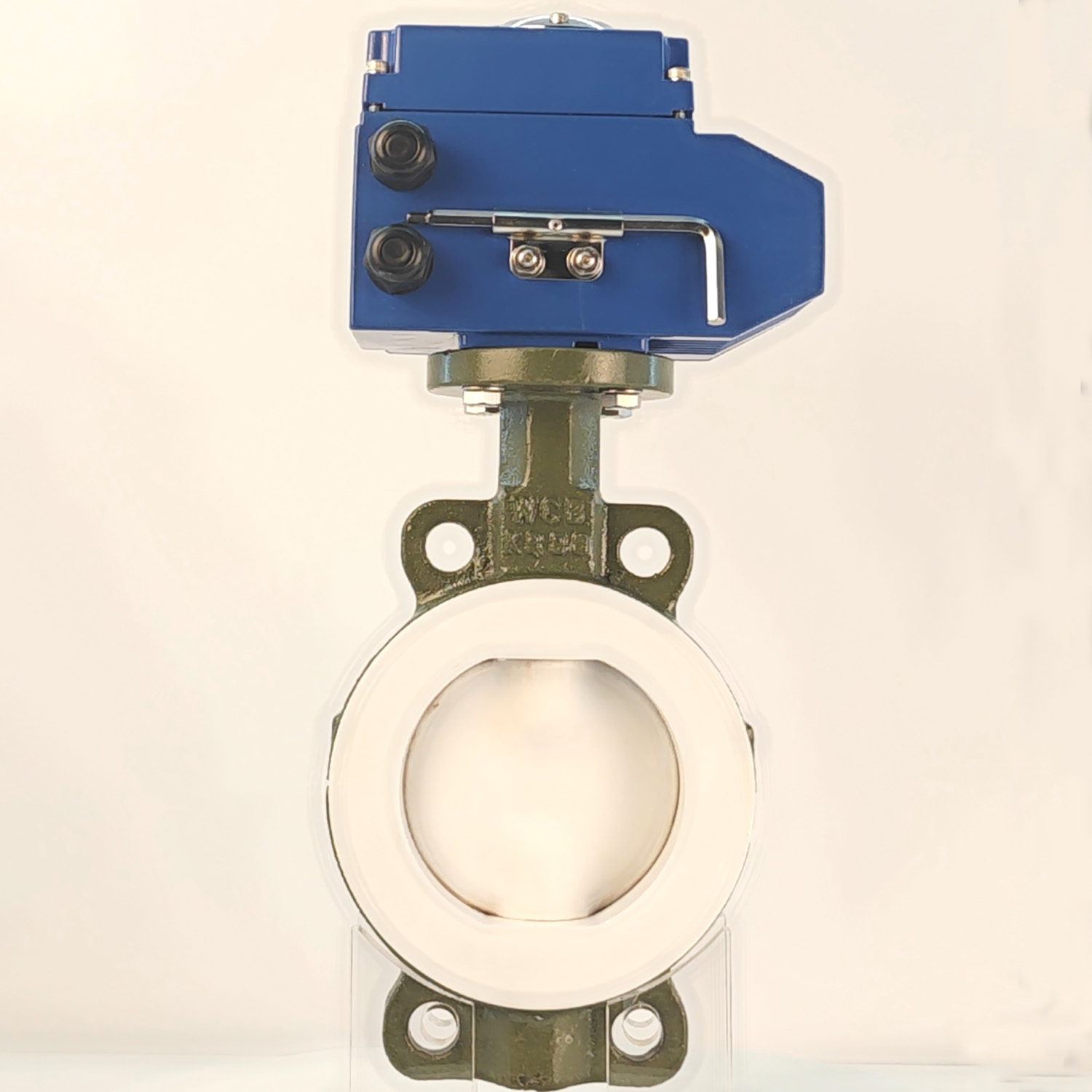

Electric All-Film Fluorine PTFE Sealing Butterfly Valve

- Controls fluid on/off or regulates flow by rotating the butterfly plate

- Designed for harsh corrosive, high-purity, or high-temperature media environments

- Electric Valve SUS304

Product Overview

The electric all-film fluorine butterfly valve is a type of valve that controls fluid on/off or regulates flow by rotating the butterfly plate. The valve seat, butterfly plate, and all media-contacting components are lined with fluoroplastics (such as PTFE, FEP, PFA, etc.). It is specifically designed for harsh corrosive, high-purity, or high-temperature media environments, offering exceptional chemical resistance and long service life. It is suitable for automated control in demanding industrial scenarios.

Product Features

- Ultra-strong corrosion resistance: Fully fluoro plastic lining resists pH 0-14 extreme environments, suitable for strong acids, alkalis, and organic solvents.

- Zero-leakage sealing: Multi-layer elastic fluoro rubber or PTFE composite sealing structure meets ANSI/FCI 70-2 Class VI standards.

- Wide temperature range: Fluoro plastic material temperature range -50°C to +200°C (PTFE); special materials or additional cooling components can achieve higher temperatures.

- Lightweight design: Compact structure, small installation space, weight only 60% of similar metal valves.

- Intelligent control: Electric actuators support switching (ON/OFF) or regulation (4-20mA signal feedback, Modbus communication).

Technical Parameters

| Parameter Name | Parameter Value Description |

| Nominal Diameter (DN) | DN50~DN1200 (custom large sizes supported) |

| Nominal Pressure (PN) | PN6~PN16 (up to Class 300 with special design) |

| Temperature Range | -50°C~+200°C (PTFE lining) / -30°C~+150°C (FEP lining) |

| Applicable Media | Strong acids, strong alkalis, organic solvents, high-purity liquids, high-temperature gases, etc. |

| Connection Method | Flanged (ANSI, DIN, GB standards), wafer type |

| Leakage Class | ANSI/FCI 70-2 Class VI (zero leakage) |

| Actuator Type | Switching type (ON/OFF), regulating type (proportional control), optional explosion-proof certification (ExdMCT6). |

Application

Media Types

- Strong acids (sulfuric acid, hydrochloric acid, nitric acid, etc.), strong alkalis, organic solvents, mixed corrosive media.

- High-purity liquids (pharmaceutical, food-grade media compliant with FDA, GMP standards).

- High-temperature gases or liquids (temperature range adjusted based on fluoro plastic type).

Application Fields

- Chemical industry: Corrosive medium conveying systems.

- Pharmaceutical/Food: Sterile pipelines, high-cleanliness fluid control.

- Environmental engineering: Acid-base wastewater treatment systems.

- Electroplating/Metallurgy: Electrolyte, corrosive gas pipelines.

Installation Requirements

- Pre-treatment: Thoroughly clean the pipeline before installation to avoid scratching the fluoro plastic layer with welding slag or hard particles.

- Alignment: Symmetrically and evenly tighten flange bolts to prevent valve body deformation affecting sealing performance.

- Flow Direction: Valve body arrow direction must align with medium flow direction (bidirectional sealing by default if no arrow).

- Welding Protection: Prohibit welding near the fluoro plastic valve body to prevent high temperatures from damaging the fluoro plastic layer.

- Maintenance Space: Reserve space for actuator operation and maintenance to ensure unobstructed full-open/full-close operation.

Package

Plywood Case or Paper carton

Our Service

- Warranty Period: 12 months (for non-human damage or improper use).

- Technical Support: Free installation guidance, troubleshooting, and lining repair solutions.

- Spare Parts Supply: Long-term supply of wear parts such as sealing rings and fluoroplastic layers.